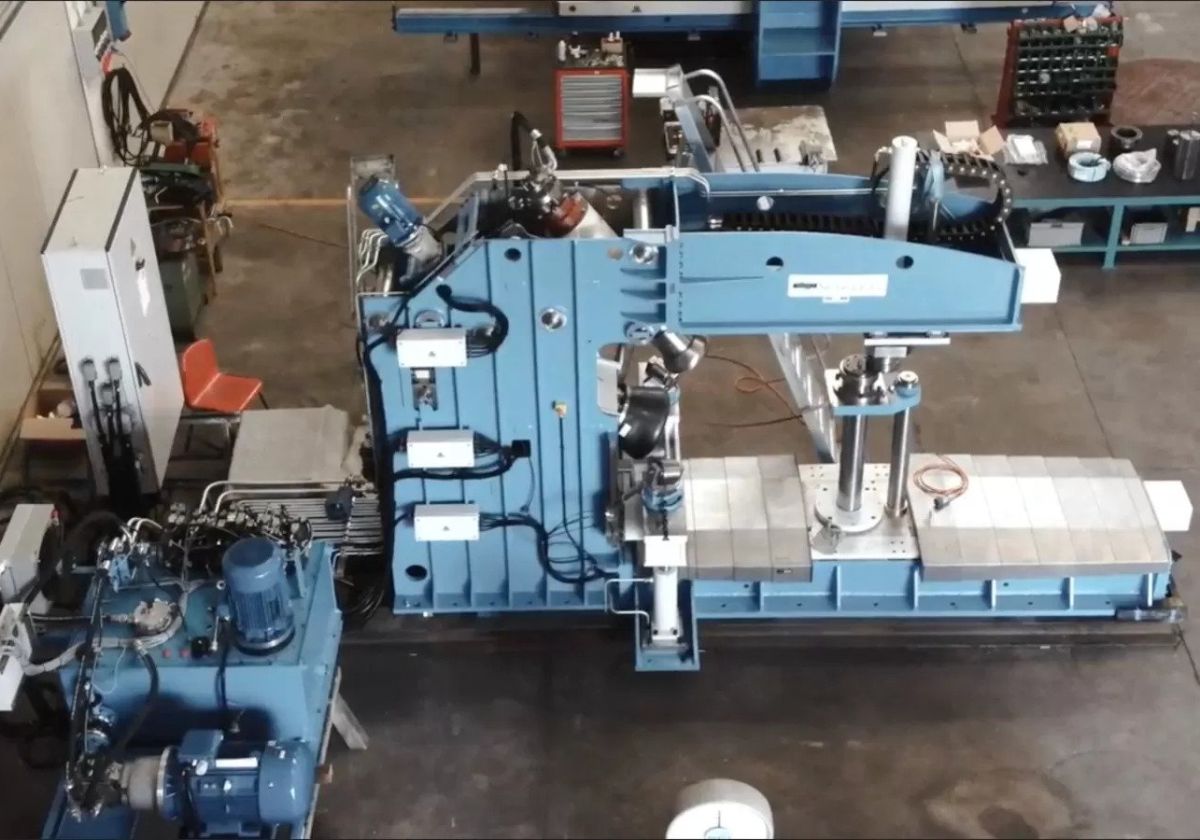

Steel plate rolling machine: deform steel in a professional way

When it comes to industrial work it is clear that technology has run its course; more and more companies invest in the purchase of cutting-edge machinery to treat their production in an optimal way, making it much more performing. The main objectives of the companies are: the safety of their personnel , efficient and rapid production , precise and impeccable production . Maximizing production in safety, limiting waste and offering top-of-the-range products is certainly the mission of companies that can achieve all this more easily by using the latest generation machinery such as Steel Plate Rolling Machine.

What is a Steel Plate Rolling Machine?

The Steel Plate Rolling Machine is a machine that proceeds to roll the steel, deforming it in a precise and professional way using rollers in order to obtain the desired result ; the goal is to limit the effort of the personnel who will simply have to set the machine correctly to obtain the right thickness in a precise and impeccable way both in terms of size and depth, obtaining high-end products.

We can speak of steel plate rolling machine with hot or cold technology . Hot rolling is able to handle higher weights and offers finished products of the highest quality ideal for automotive companies, metal constructions, parts related to the construction of houses or buildings and even agricultural equipment.

Cold rolling , on the other hand, manages to work fine on the surface finishes and manages the thickness like the previous mechanism but manages to reduce the thickness of the sheet by up to 50%. This technology is used for example for the production of parts related to the production of motorcycles, furniture or metal equipment and also small sized productions such as hinges.

How does it work

The steel plate rolling machine is used to produce plates of various thicknesses . These plates are commonly used in agricultural, transportation, construction and manufacturing applications. Steel sheets can be used to create different structures and products. They can be used to build barns, create tractor tires, build bridges and more. Steel sheets are also used in agricultural and manufacturing industries.

What are the benefits

– Versatility – Steel plate rolling machines can be used to produce plates of varying thickness. This allows them to be used in a wide range of industries and applications.

– Ease of use – Steel plate rolling machines are relatively easy to use. They can be operated by a single operator and are generally easy to maintain. This allows its use in various industrial sectors, such as agriculture and construction.

– Low cost – Steel plate rolling machines are relatively inexpensive. This makes them accessible to a wide range of industries.

– Safe to use – Steel plate rolling machines are relatively safe to use. The risk of injury or accident is minimal.

– Low noise levels – Steel plate rolling machines produce low noise levels. This allows it to be used in residential and commercial areas.

– Wide variety of applications – Steel plate rolling machines can be used to produce plates of various thicknesses. This allows them to be used in a wide range of industries and applications.

– High Production – Steel Plate Rolling Machines produce high production. They can produce a large number of steel plates in a single day.

– High quality – Steel plate rolling machines produce high quality steel plates. This ensures that the final product is strong and durable.